The Digital Battery Passport

Sustainability and digitalisation in the industrial battery market

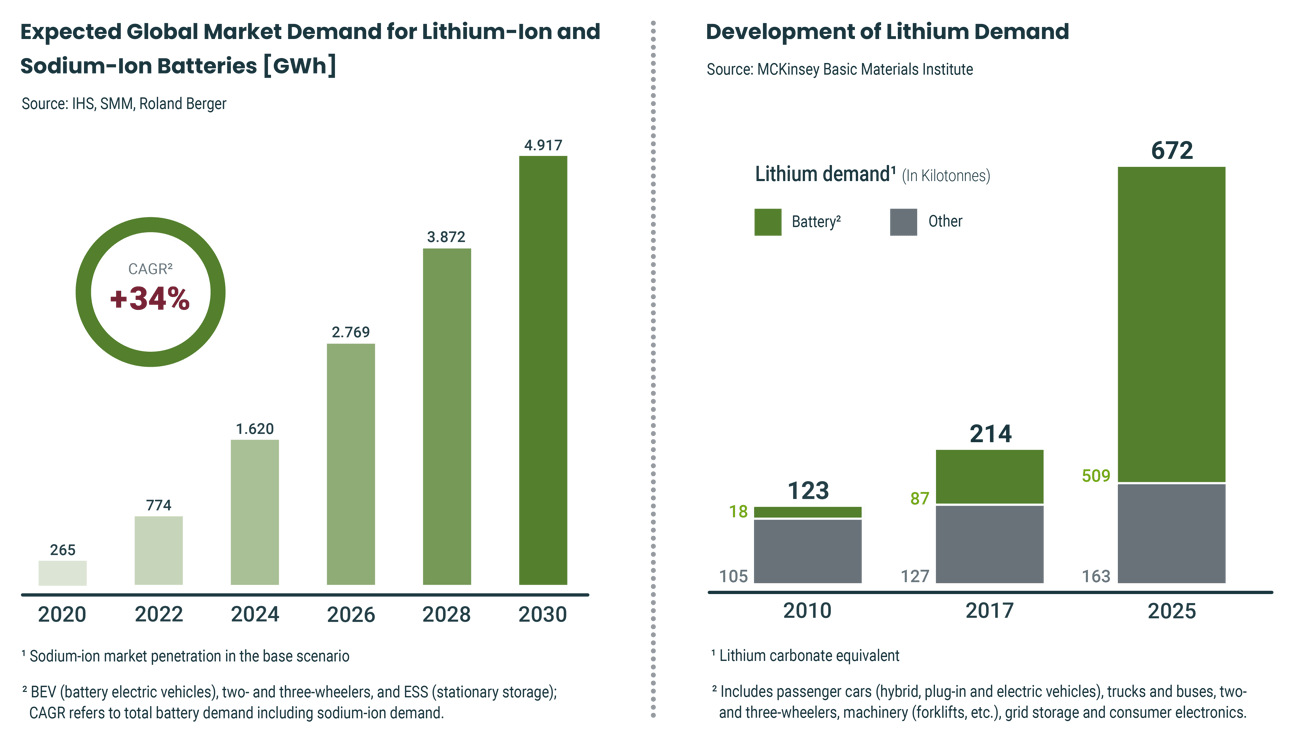

Transport and industry aim to accelerate electrification in order to reduce reliance on fossil fuels. This will lead to a sustained increase in demand for batteries. The European Parliament intends to ban sales of combustion engine cars from 2035. As a result, demand for battery materials such as lithium, cobalt, nickel and copper is rising.

Sustainable handling of batteries across the entire value chain - from raw material extraction to recycling - is urgently needed.

Forecasts suggest that demand for lithium will increase roughly 28-fold when comparing 2017 with 2025. Demand for lithium-ion batteries is also expected to grow dramatically in the coming years. The drivers of this growth are increased electromobility (for instance, traction batteries) and the expansion of renewable energies.

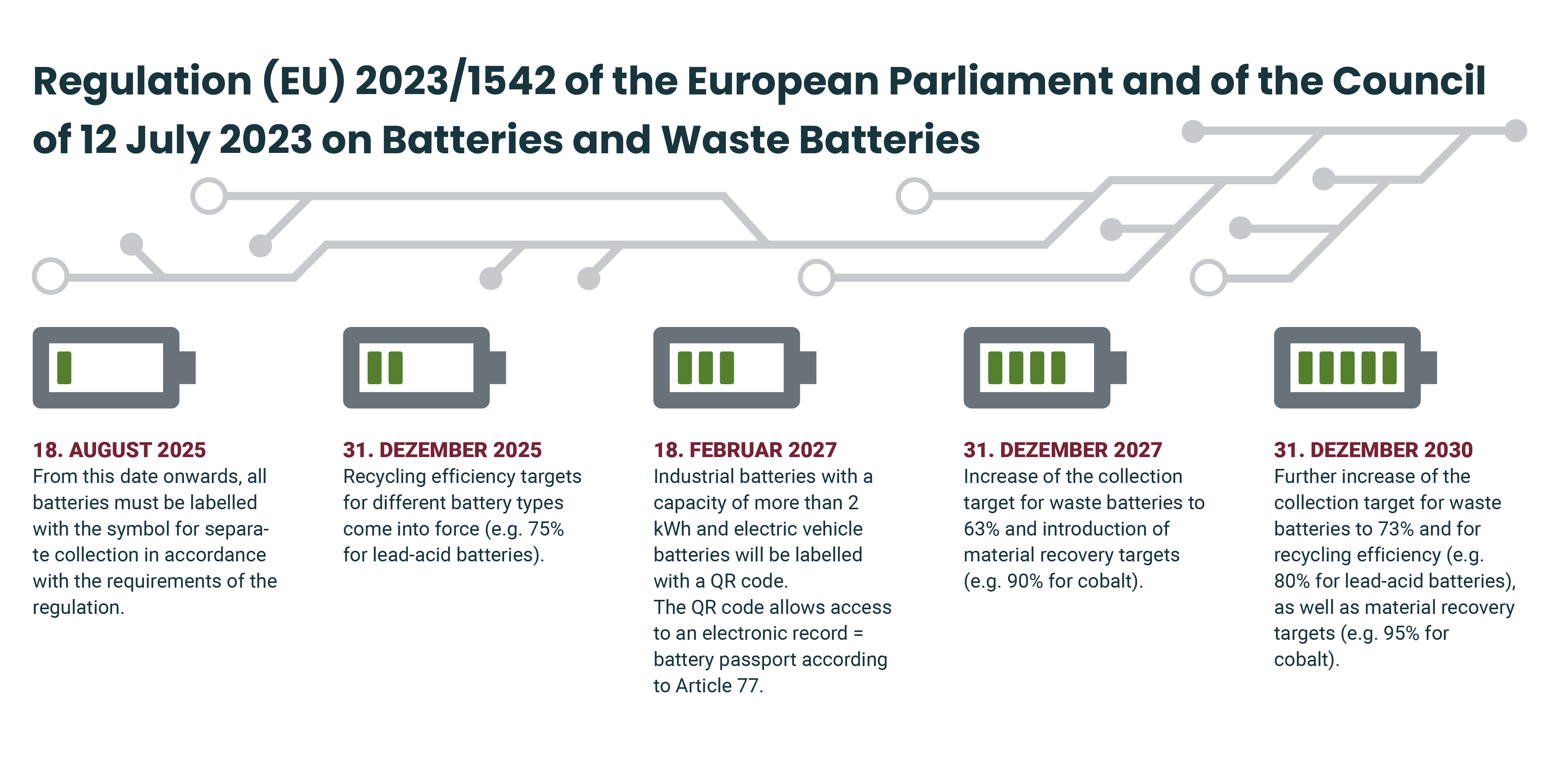

The battery passport will become mandatory for all batteries above 2 kWh capacity.

Digital Battery Passport FAQ

Our Digital Battery Passport frequently asked questions section brings together answers to the key questions on the Battery Passport.

What is the Digital Battery Passport?

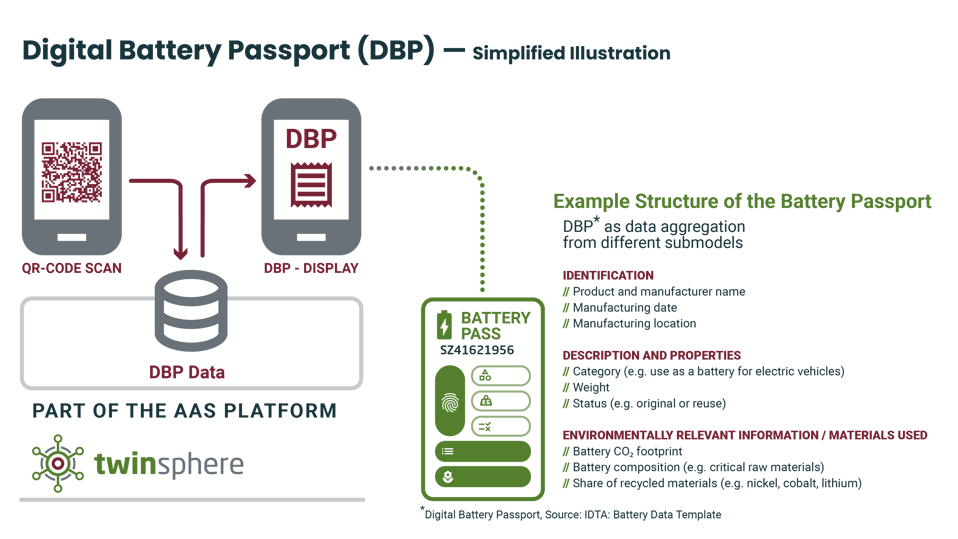

The future battery passport is an official document (analogous to an identity card) that follows a battery throughout its entire lifecycle and contains information from manufacture to disposal.

As a practical example, consider the scrapping of an electric car whose battery is given a second life in a photovoltaic system. That battery would receive a new battery passport, which is linked to the original one to ensure digital traceability.

How is the Digital Product Passport (DPP) related to the Digital Battery Passport (DBP)?

In essence, the battery passport is a specific use case of the Digital Product Passport, which is being developed under EU initiatives for more sustainable product design and stronger circular economies. The battery passport is part of the European Union’s strategy to improve product sustainability by introducing digital product passports, as defined in the Ecodesign for Sustainable Products Regulation (ESPR).

For which types of batteries does the Digital Battery Passport apply?

The battery passport applies to traction batteries, industrial batteries, and batteries for light vehicles, each with a capacity of 2 kWh or more. The data of such batteries must then be digitally represented (as a so-called "digital twin") so that they can be made available interoperably across the value chain, for example to the manufacturer’s customers.

What benefits does implementing the Digital Battery Passport bring?

The primary advantage for companies is greater data transparency. This not only contributes to the EU’s overarching goals of promoting a circular economy, reducing carbon footprint, and achieving climate neutrality, but can also simplify internal business processes, enable better decisions, and possibly lead to cost savings.

The battery passport is designed to accelerate digital efforts of participants along the battery value chain, ultimately ensuring interoperable data provision. In sum, data input from as many participants in the value chain as possible is required.

Only in this way can the battery passport display valid data, enable meaningful battery recycling, and ultimately serve as a functional example of a circular economy.

What challenges exist?

Concerns around the battery passport generally fall into areas such as time pressure, the need for a performant and scalable system landscape, IT security concerns, or excessive regulatory burden. Especially for medium-sized companies, complexity and implementation costs are often seen as challenges. Additionally, the expected benefits are still difficult to quantify precisely.

Further influencing factors include differing interests in technological, business policy or national contexts. Nevertheless, due to binding EU regulations, companies will not be able to avoid adopting the battery passport. Because achieving long-term climate neutrality requires taking the first steps now.

What is the current status of the battery passport?

The consortium project Battery Pass, co-funded by Germany’s Federal Ministry for Economic Affairs and Climate Action, aims to develop both content and technical standards for implementing the Digital Battery Passport, and to illustrate these via a pilot project.

At Hannover Messe 2024, a demonstrator was also presented. Through involvement of industry, technology and academia, the project ensures that the battery passport is feasible for industrial stakeholders while reflecting the ecological and economic advantages of the Digital Product Passport.

What is the timeline?

Under the EU Battery Regulation, binding implementation is expected from 2027 onwards; in the best case, preparatory steps should begin immediately.

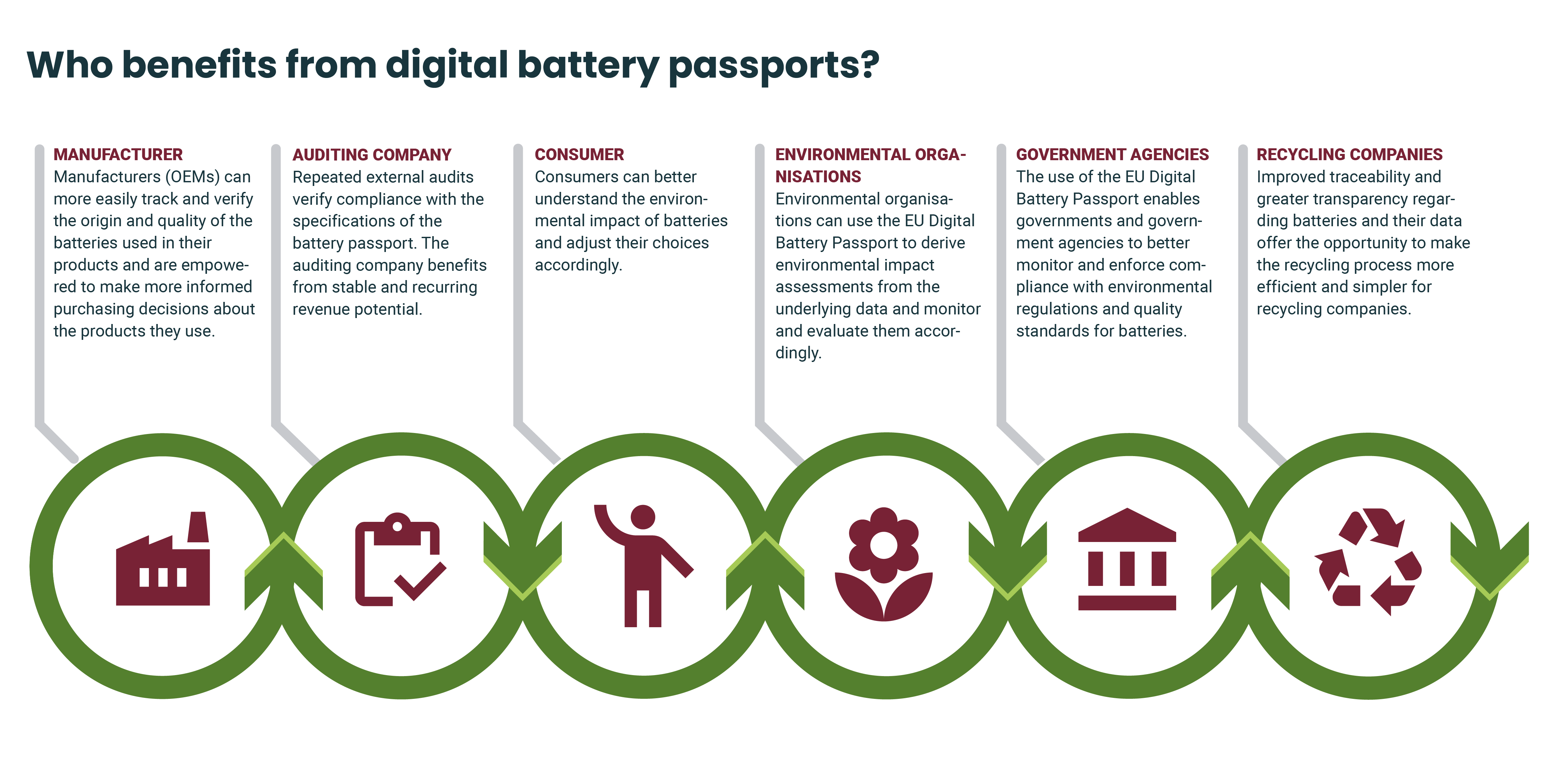

Who benefits from the battery passport?

A wide range of actors stand to benefit from the battery passport and the data it contains. In addition to end users, manufacturers (OEMs), recycling companies (in the context of battery recycling), environmental organisations and even governments or regulatory agencies benefit from increased data transparency.

The value of implementing the DBP varies depending on the stakeholder. The so-called “value assessment”, i.e. evaluating benefit scenarios per stakeholder group, is under investigation by the consortium project and is expected to be explored in depth by end 2024. For recycling companies, it is already assumed today that around 20 % of process costs could be reduced, provided the relevant data for each battery is available.

In summary, the battery passport is a milestone on the path toward a more sustainable world, higher recycling rates for critical raw materials such as lithium, cobalt, nickel and copper. Beyond regulatory pressure, recycling holds significant potential to evolve into a viable, profitable and sustainable business model.

How can the implementation of the battery passport look from a customer’s perspective?

The battery passport can be accessed in future via a QR code, giving information on battery-specific data and additional details such as descriptions of battery condition (age, quality and usage evidence as original battery or reused battery).

Sustainability information - for example, CO₂ footprint and material composition as well as recyclability - will also be displayed. Because improving working conditions in raw material extraction (due diligence) is also an aim, these aspects are conceptually included. In this regard, the new sub-model Digital Battery Passport under the IDTA is currently in focus.

Once this sub-model is published, implementation of the Digital Battery Passport can be advanced with our SaaS platform twinsphere.

Thomas Wahle

Vorstand

Britta Waligora

Vorstand

Christian Günther

Innovation & Portfolio Architect, TOPIC OWNER Digital Twin